REVERSE ENGINEERING

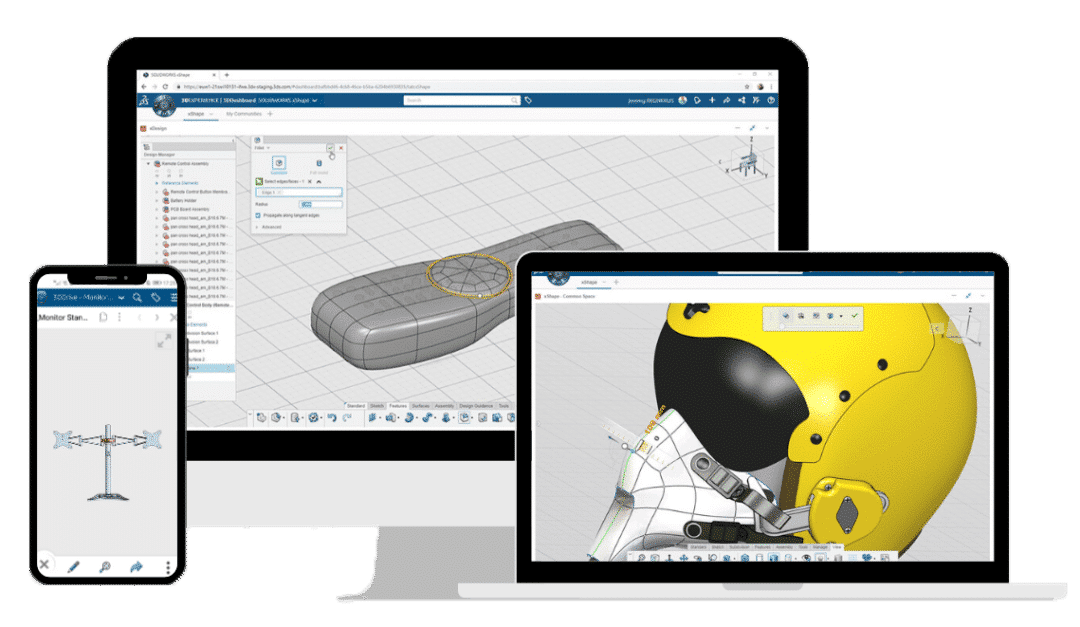

Reverse Engineering introduces candidates to essential concepts of reverse engineering and digitized data processing. The course emphasizes hands-on techniques for creating and refining 3D models from scanned data, providing insights into industrial applications. Through the use of advanced tools like CATIA 3DEXPERIENCE, candidates will learn to work with point clouds, generate surfaces, and develop solid models, enhancing their ability to create manufacturable designs from physical objects.

Key Points

🟢 Fundamentals of Reverse Engineering: Learn the core principles of reverse engineering, its industrial evolution, advantages, and limitations.

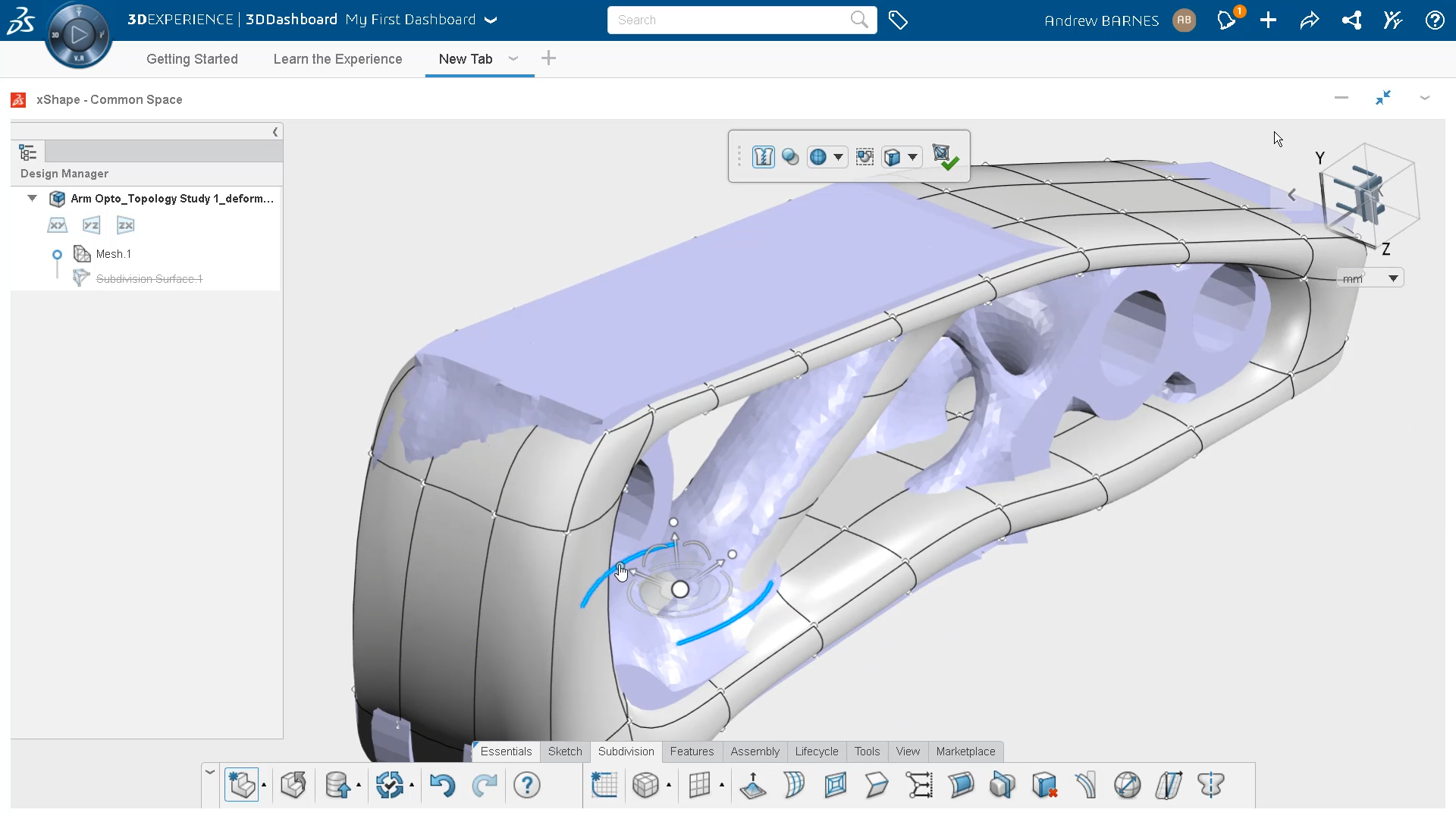

🟢 Working with Digitized Data: Understand the process of importing scanned data, refining the mesh, and creating surface networks while controlling deviations.

🟢 Cloud Points: Gain hands-on experience with CATIA digitized shape preparation, processing, meshing, and aligning clouds-points to develop precise digital models.

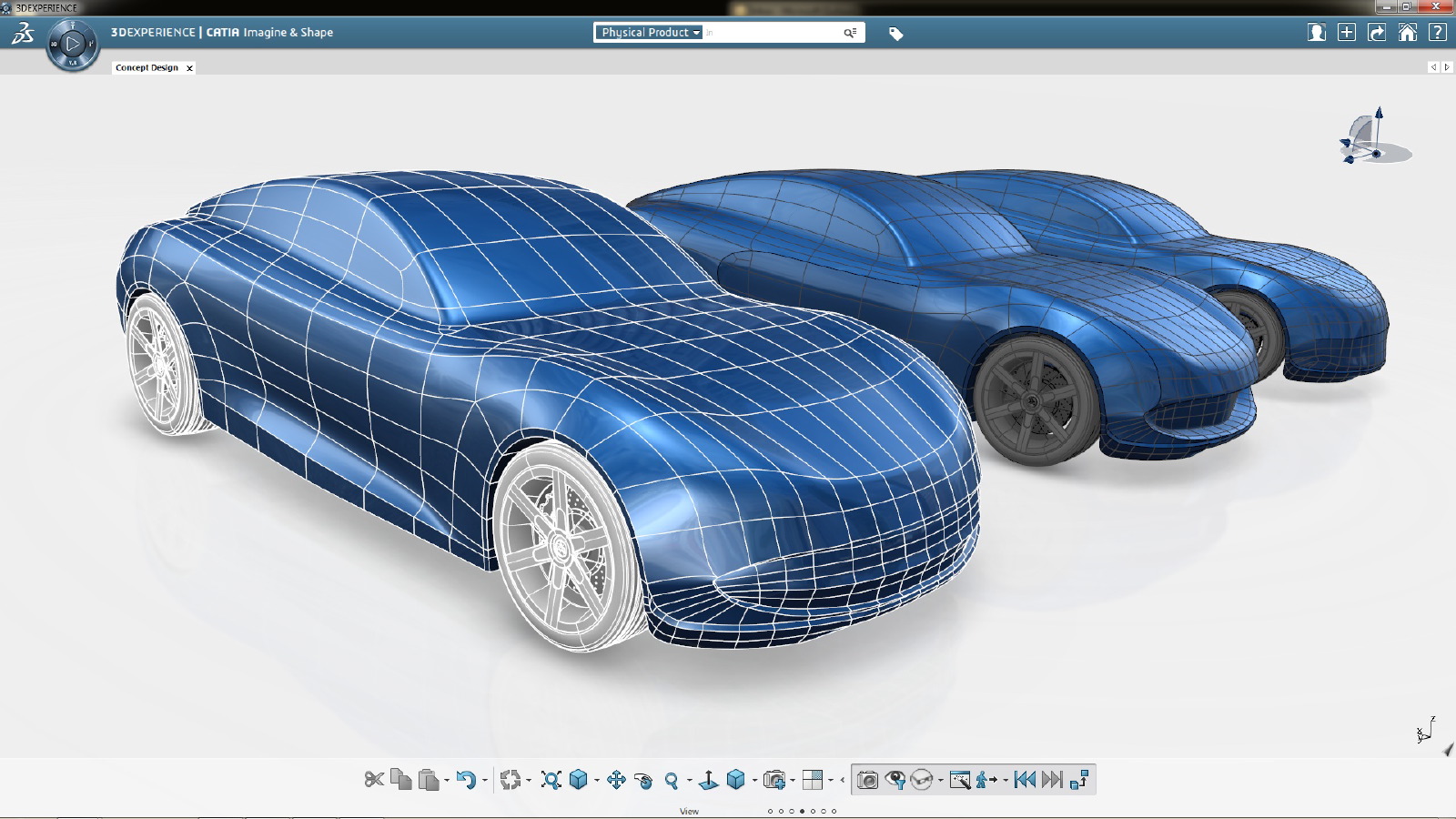

🟢 Surface Creation Techniques: Explore surface creation methods, including untrimmed surfaces, mechanical shapes, and advanced solid modeling techniques.

🟢 Surface and Solid Design: Master surface creation using various approaches, including power fitting, trimming, and filleting, to generate complex 3D models.

🟢 Deviation Analysis: Learn to analyze and control deviations in 3D models to ensure accuracy and quality in the final product.

🟢 Practical Applications: Apply the learned techniques to real-world tasks, such as processing scanned data into usable surfaces and creating solid models ready for manufacturing.

CONCLUSION

By the end of this course, candidates will have gained comprehensive knowledge and practical skills in reverse engineering, digitized data processing, and surface creation. Mastery of these techniques will prepare candidates to handle complex designs and develop manufacturable 3D models using industry-standard tools like CATIA.

- Teacher: Admin Msl